How to Select the Best Geomembrane for Your Project: A Complete Guide

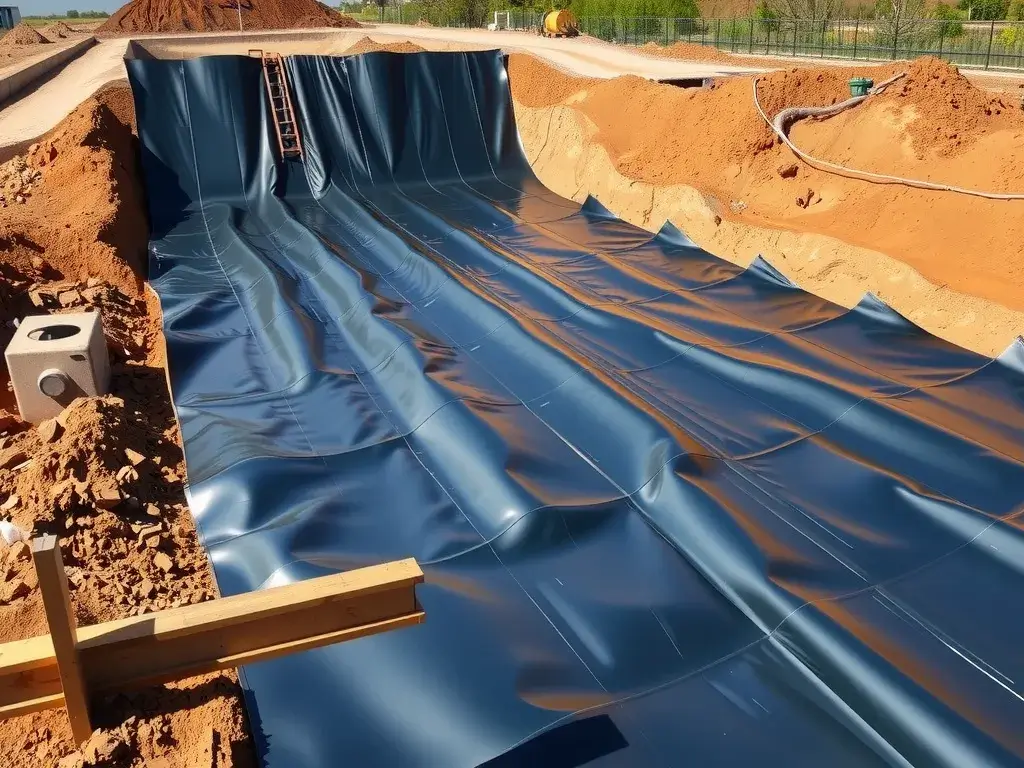

Picking the right geomembrane is crucial for your project’s success and reliability. Geomembranes are utilized across various sectors—from mining to aquaculture—to offer vital environmental protection and containment. This guide highlights the main factors to consider when selecting a geomembrane so you can match the product with your project needs. They act as engineered barriers against leaks, protecting soil, groundwater, and long-term regulatory compliance.

Understanding Geomembrane Options

Geomembranes are primarily made from High-Density Polyethylene (HDPE) or Linear Low-Density Polyethylene (LLDPE). Each material provides distinct benefits: Other polymers exist, but these two dominate due to proven performance and availability.

-

HDPE Geomembranes:

Known for excellent impermeability and strong resistance to chemicals, making them perfect for landfill liners and mining tasks. They deliver high tensile strength and durability, but need precise seaming and thermal expansion management during installation.

They deliver high tensile strength and durability, but need precise seaming and thermal expansion management during installation.

-

LLDPE Geomembranes:

Offer more flexibility, which is suitable for projects needing to adapt to uneven surfaces. Greater elongation accommodates settlement and movement, and can improve puncture resistance on variable subgrades.

Greater elongation accommodates settlement and movement, and can improve puncture resistance on variable subgrades.

-

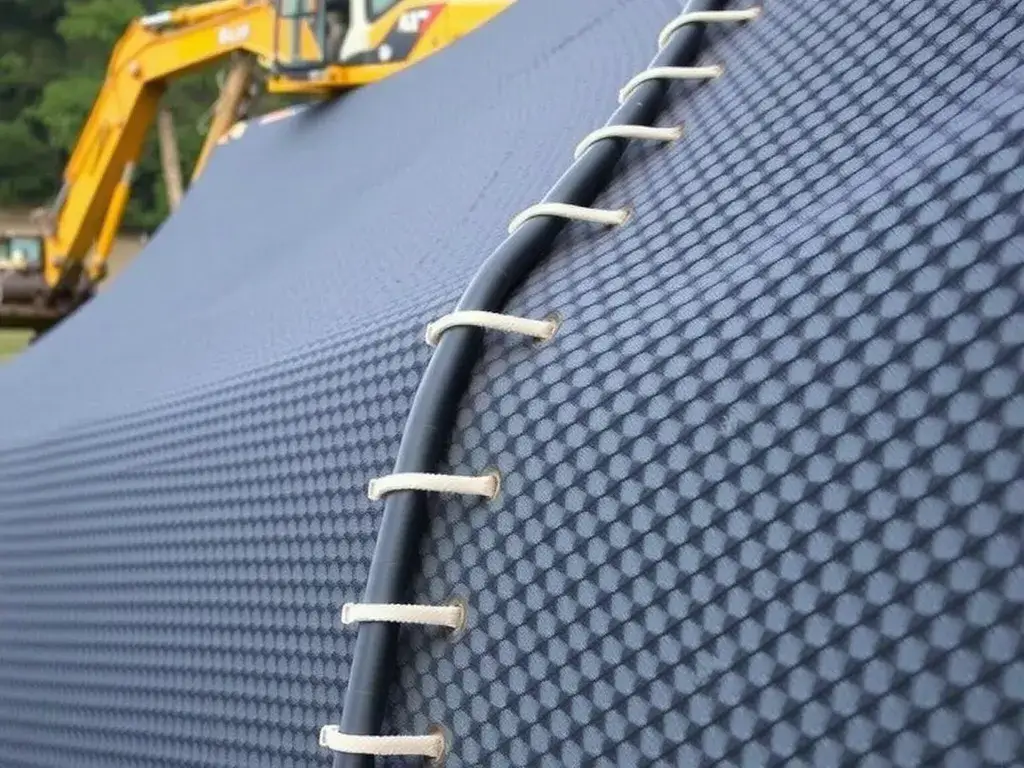

Textured vs Smooth:

Textured geomembranes enhance friction, boosting stability on slopes or steep areas. Smooth surfaces, by contrast, are easier to clean and often preferred where sediment removal is frequent.

Smooth surfaces, by contrast, are easier to clean and often preferred where sediment removal is frequent.

Match the material and surface texture to the environmental needs and physical conditions at your site. Also consider settlement, subgrade quality, slope angles, and compatibility with process fluids.

Evaluating Project Requirements

A detailed analysis of project-specific requirements is essential before choosing a geomembrane. Consider the following: Early input from designers and installers improves outcomes.

-

Environmental Conditions:

Assess temperature ranges, possible chemical contact, and UV resistance needs. Include freeze–thaw cycles, sunlight intensity, pH or hydrocarbon exposure, and antioxidant package needs for long-term aging. -

Application Area:

The intended use—like pond lining or waste containment—will guide the selection of material and thickness. Loading, hydrostatic head, and puncture risks drive thickness; many designs add geotextile cushions or leak detection layers. -

Budget Considerations:

Balance cost with performance and lifespan to make a wise, economical choice. Weigh life-cycle cost, warranty terms, installation speed, and logistics such as lead times, panel sizes, and shipping.

Aligning your selection with these factors helps ensure effective performance and cost-efficiency. It also reduces construction risk and supports predictable schedules and maintenance planning.

Technical and Regulatory Standards

Adhering to industry standards ensures safety, durability, and project credibility. Geomembranes should meet or surpass benchmarks such as GRI-GM13 for HDPE and GRI-GM17 for LLDPE. Understanding these standards helps you choose products that meet regulatory requirements and support sustainable project execution. Request third‑party reports and ASTM data. Plan CQA/CQC with trial seams and vacuum box or air‑pressure tests.

Case Study Example

Consider a large agricultural project in Saudi Arabia where selecting the right geomembrane was crucial. After evaluating soil conditions and UV exposure, the team chose textured HDPE geomembranes, achieving durability and reduced soil erosion. The result was a strong, environmentally compliant solution that sped up timelines while remaining cost-efficient. A geotextile underlayment cushioned sharp aggregates, and leak location surveys verified liner integrity before filling, minimizing repairs and simplifying inspections.

After evaluating soil conditions and UV exposure, the team chose textured HDPE geomembranes, achieving durability and reduced soil erosion. The result was a strong, environmentally compliant solution that sped up timelines while remaining cost-efficient. A geotextile underlayment cushioned sharp aggregates, and leak location surveys verified liner integrity before filling, minimizing repairs and simplifying inspections.

Conclusion

Selecting the right geomembrane requires a thorough understanding of material options, project-specific needs, and applicable standards. When you align your project’s requirements with the suitable geomembrane, you support both immediate success and long-term sustainability. For expert advice and customized solutions, consult our team at Factories GPF to find the best options for your needs. Engage suppliers early, request mock-ups, and document an installation and maintenance plan.