Creative Use of Geomembranes in Aquaculture for Better Sustainability

As global aquaculture grows, sustainability has become a top priority. For those interested in effective, eco-friendly water management, geomembranes provide a practical and innovative solution. Specifically, High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) geomembranes are key materials promoting more sustainable aquaculture practices. By separating culture water from native soils and groundwater, liners let farmers control salinity, recapture and treat effluent, and reduce withdrawals. They also streamline biosecurity by making ponds easier to disinfect between cycles and by limiting pathogen harborage in porous subgrades. HDPE offers long‑term UV stability, while flexible LLDPE conforms to complex pond shapes, supporting farms, hatcheries, and RAS facilities.

By separating culture water from native soils and groundwater, liners let farmers control salinity, recapture and treat effluent, and reduce withdrawals. They also streamline biosecurity by making ponds easier to disinfect between cycles and by limiting pathogen harborage in porous subgrades. HDPE offers long‑term UV stability, while flexible LLDPE conforms to complex pond shapes, supporting farms, hatcheries, and RAS facilities.

The Importance of Geomembranes in Aquaculture

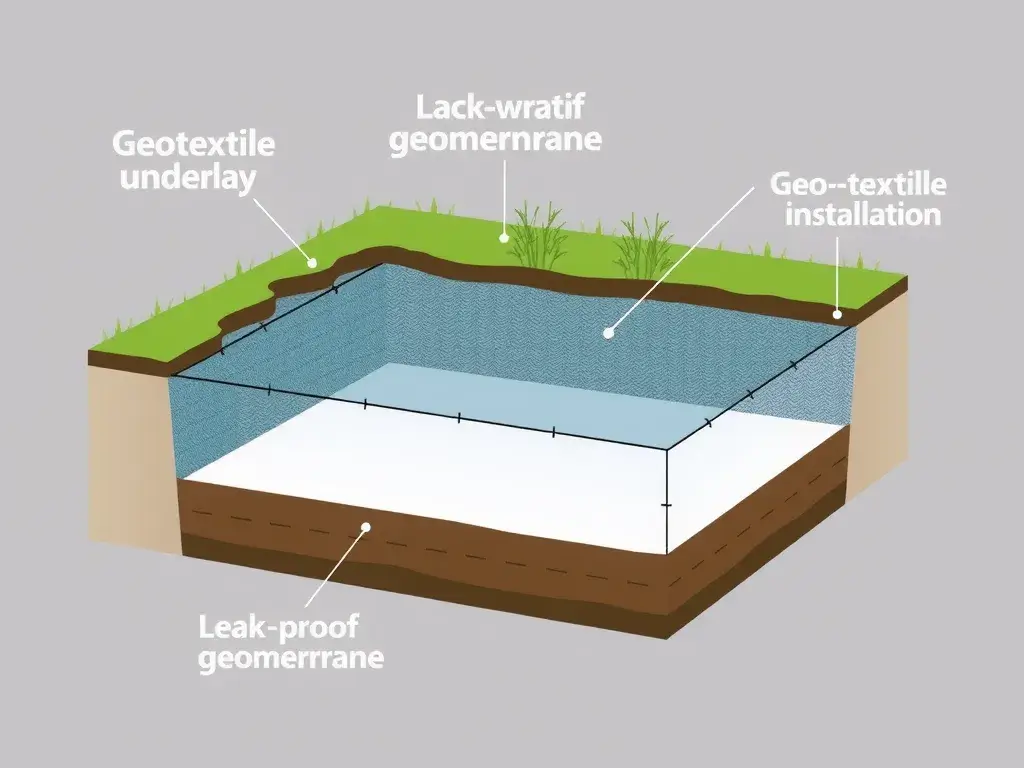

In aquaculture, geomembranes are increasingly used to create secure areas that maintain water quality and lower environmental impact. By forming a leak-proof barrier, these liners stop seepage and contamination, protecting both aquatic life and the surrounding environment. This method is especially crucial in areas where water conservation and environmental protection are essential. Lined basins and raceways prevent seepage that can salinize soils or load nutrients into groundwater. Smooth, nonporous surfaces speed sludge removal and disinfection between cycles, strengthening biosecurity and reducing off‑flavor risks. In rocky sites, a cushioning geotextile underlayment reduces puncture risk and extends service life.

In rocky sites, a cushioning geotextile underlayment reduces puncture risk and extends service life.

Environmental Advantages and Long-term Sustainability

Using geomembranes in aquaculture reduces water waste and enhances environmental management while boosting operational efficiency. HDPE and LLDPE geomembranes comply with industry standards like GRI-GM13 and GRI-GM17 and offer durability and chemical resistance—qualities vital for sustaining healthy aquaculture settings. By implementing these systems, aquaculture ventures can significantly cut their carbon footprint and running costs. Beyond compliance, these polymers resist UV, salts, fertilizers, and many common disinfectants. Properly welded seams—made by hot wedge or extrusion—form continuous barriers verified with routine air‑channel or vacuum testing. Lower seepage stabilizes water chemistry, reducing make‑up water, energy use, and treatment frequency while improving animal performance.

Real-world Applications and Examples

Geomembranes have been effectively used in fish farming and hatcheries. For instance, fish farming businesses in the Middle East have employed geomembrane-lined ponds to boost water retention and quality, resulting in healthier fish populations and increased production. These examples demonstrate the material’s capacity to support sustainable growth while adhering to both local and international environmental regulations. Shrimp nurseries see faster turnarounds because lined ponds wash and sanitize quickly. Hatcheries line settlement ponds to capture fines during storms, while farms use liners for harvest sumps and sludge beds, consolidating waste for composting and limiting nutrient leaching that can trigger algal blooms. In arid regions, lined reservoirs paired with floating covers help curb evaporation and keep salinity stable.

These examples demonstrate the material’s capacity to support sustainable growth while adhering to both local and international environmental regulations. Shrimp nurseries see faster turnarounds because lined ponds wash and sanitize quickly. Hatcheries line settlement ponds to capture fines during storms, while farms use liners for harvest sumps and sludge beds, consolidating waste for composting and limiting nutrient leaching that can trigger algal blooms. In arid regions, lined reservoirs paired with floating covers help curb evaporation and keep salinity stable.

Future Opportunities and Innovations

Looking forward, the future for geomembranes in aquaculture is promising. Advances in material science are expected to offer even more sustainable and efficient products, enabling tailored solutions for specific regional needs. These innovations are poised to help transform aquaculture into a leading industry for environmental care, especially in regions like Saudi Arabia, where water management is crucial. Innovations include multilayer, co‑extruded membranes that balance toughness and flexibility, and conductive options that enable leak‑location surveys after installation. Textured surfaces improve traction on slopes, while water‑level and salinity sensors complement lined systems, enabling data‑driven exchange rates and aeration schedules. Expanded installer training and certification further ensure that design and seaming practices match material capabilities.

In summary, adopting geomembranes in aquaculture shows the sector’s dedication to sustainability and efficiency. By using the strengths of HDPE and LLDPE liners, aquaculture operations can progress toward a more sustainable future, setting an example in environmental responsibility and operational excellence. Economically, reduced seepage and faster turnarounds support higher stocking densities and consistent yields. Robust liners also help satisfy discharge permits and buyer requirements. With sound anchoring, freeboard design, and planned sludge handling, HDPE and LLDPE provide a resilient foundation for dependable, year‑round production and community‑level food security.