Creative Uses of Geomembranes in Aquaculture

Aquaculture is expanding quickly as the need for sustainable, effective seafood grows. To address this demand, practical innovations are crucial—and geomembranes are at the forefront. High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) liners offer excellent durability, dependable water retention, and strong environmental protection, making them ideal for a variety of aquaculture uses. Beyond basic containment, these liners enable more predictable production cycles by stabilizing salinity, temperature, and turbidity profiles. The result is a platform that lets producers fine-tune feeding, aeration, and stocking density with greater confidence, ultimately turning variable ponds into consistent, data-driven production assets.

Creative Applications in Aquaculture

Geomembranes are transforming fish farming, shrimp cultivation, and water quality management. A major use is lining ponds and raceways to maximize water retention and cut down on seepage. This is especially important in dry regions like the Middle East, where conserving water is crucial. Liners also perform in brackish and marine ponds, preventing salt intrusion into soils and maintaining target salinity for sensitive species. Operators deploy them in nursery and quarantine units, settlement basins, harvest sumps, and even lined canals that move water between ponds, ensuring every liter is directed and accounted for rather than lost to the subgrade.

They also assist in maintaining water quality by preventing contamination from surrounding areas. Their impermeable nature supports a controlled aquatic environment, reducing disease risk and boosting overall yield. Lined bottoms make sludge removal faster and more thorough, limiting anaerobic zones and off-flavors; smooth surfaces discourage unwanted biofilm while still allowing strategic biofloc development where desired. GPF’s geomembrane products provide solutions tailored to aquaculture needs, improving operational efficiency and sustainability. Options include textured or smooth finishes, light- and dark-colored surfaces for thermal management, custom-fabricated panels to speed installation, and accessories that integrate with drains, central sumps, and aeration equipment to create a coherent, maintainable system.

Benefits of HDPE and LLDPE Liners

HDPE and LLDPE liners are known for their strength, flexibility, and resistance to chemical and UV degradation, making them perfect for aquaculture facilities. These liners extend the life of ponds and contribute to cost savings by minimizing upkeep. HDPE offers outstanding mechanical strength and long-term dimensional stability, ideal for large cells and steeper embankments, while LLDPE provides superior flexibility for irregular basins and colder conditions. Thermal fusion welding creates robust, leak-tight seams, and standard quality checks—such as vacuum box testing and spark testing—help verify integrity, reducing unplanned downtime and protecting stock.

Moreover, using sustainable geomembranes supports eco-friendly aquaculture practices. Their non-toxic makeup prevents harmful substances from leaching into the water, creating a healthier environment for aquatic life. Implementing these liners aligns with sustainable aquaculture goals, balancing productivity with environmental preservation. Efficient water use, lower chemical inputs through better solids control, and targeted therapeutant dosing all contribute to reduced environmental footprint. The long service life of high-quality liners means fewer replacements and less material waste over time, and end-of-life recycling pathways further enhance circularity efforts for responsible producers.

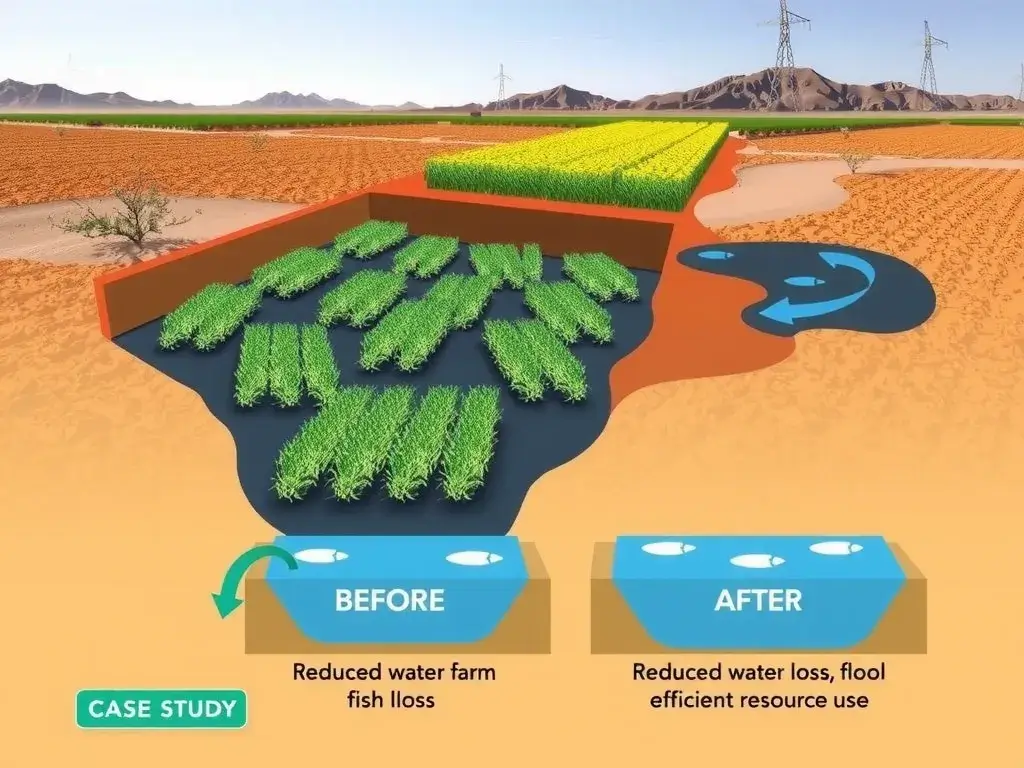

Case Study: Effective Implementation

A recent project in Saudi Arabia showcased the successful use of geomembranes to boost aquaculture productivity. By installing HDPE liners in fish breeding ponds, the facility reduced water loss by over 30% and enhanced fish growth rates through improved water quality management. Subgrade preparation, a protective geotextile cushion, and carefully welded seams limited punctures and ensured long-term performance. Operators reported cleaner bottoms, quicker harvests, and more reliable dissolved oxygen profiles, enabling tighter feeding schedules and a measurable improvement in feed conversion ratios. With fewer water exchanges, energy consumption for pumping decreased, and the investment achieved payback within two production cycles. This case underscores GPF’s dedication to providing geomembrane solutions that meet the specific needs of the aquaculture industry.

Conclusion

As aquaculture continues to grow, integrating innovative geomembrane solutions is vital. By taking advantage of the unique properties of HDPE and LLDPE liners, facilities can achieve better performance and sustainability. These materials enhance productivity while supporting environmental conservation goals. Whether retrofitting a legacy pond or building a new site, careful liner selection, expert installation, and routine inspection create dependable, predictable systems. Contact GPF today to learn how our geomembrane solutions can transform your aquaculture operations, from conceptual design and material selection to onsite support and long-term maintenance planning.