Technical Details and Certification Standards of Geomembranes for Mining Applications

In mining, where economic and environmental stakes are high, certified geomembranes are essential. Knowing specifications and certifications supports performance and compliance from feasibility through closure. Because liner failures cause downtime, remediation, and regulatory scrutiny, selecting proven materials is a strategy for resilience and long‑term cost control, not a simple purchase. Certification aligns materials with permit conditions, simplifies design reviews, and clarifies responsibilities between owner, engineer, and contractor. It also helps forecast maintenance budgets and schedule contingencies.

Understanding Geomembrane Technical Certifications

Geomembranes used in mining must adhere to strict standards to function reliably in tough conditions. Two main certifications indicate quality and dependability: GRI-GM13 and GRI-GM17. These represent top-level standards for High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) geomembranes, respectively. GM13 targets the higher stiffness and chemical resistance profile of HDPE, while GM17 addresses the superior flexibility and elongation of LLDPE for complex subgrades or differential settlement. Both frameworks are supported by test methods commonly referenced from ASTM and ISO, helping engineers compare products using consistent, verifiable criteria. GM17’s higher elongation suits tailings covers, geomembrane‑geosynthetic composites, and areas expecting differential movement. GM13 is favored in aggressive copper or gold leach solutions where stiffness and chemical resistance are paramount.

GM17’s higher elongation suits tailings covers, geomembrane‑geosynthetic composites, and areas expecting differential movement. GM13 is favored in aggressive copper or gold leach solutions where stiffness and chemical resistance are paramount.

Certification under GRI-GM13 ensures resistance to chemical degradation, ultraviolet exposure, and environmental stresses common in mining. The standard specifies thickness, tensile strength, and puncture resistance—key features for preventing leaks and safeguarding environmental integrity. It also references properties such as oxidative induction time, carbon black content and dispersion, stress crack resistance, and dimensional stability, which collectively influence long-term durability. Reputable manufacturers pair these requirements with robust quality management and lot traceability so that each roll can be linked to resin batches, production parameters, and test records, streamlining third-party audits and construction quality assurance. Antioxidant packages and slow‑crack‑growth performance extend service life, while Manufacturer’s Quality Assurance and third‑party laboratory verification provide independent evidence of conformity. Resin selection and process control also moderate variability, improving uniformity across large projects and facilitating predictable installation performance.

Key Specifications for Mining Geomembranes

Selection hinges on chemical resistance, especially for prolonged contact with acids and reagents. Texture improves stability on heap‑leach pads and embankments. Designers also evaluate oxidizers, process temperatures, and hydrocarbon exposure across leach circuits, tailings, and solution ponds. Proper subgrade preparation—removing protrusions, adding cushioning, improving drainage—limits point loading, uplift, and premature damage.

Thickness matches puncture risk and stability; higher loads typically need thicker membranes. Width and seam overlap are controlled to limit leakage. Welding—dual‑track hot wedge or extrusion—requires field QC: destructive peel‑and‑shear tests and nondestructive air‑channel, vacuum box, or spark testing. Electrical leak surveys then verify performance before cover placement or solution start‑up.

Electrical leak surveys then verify performance before cover placement or solution start‑up.

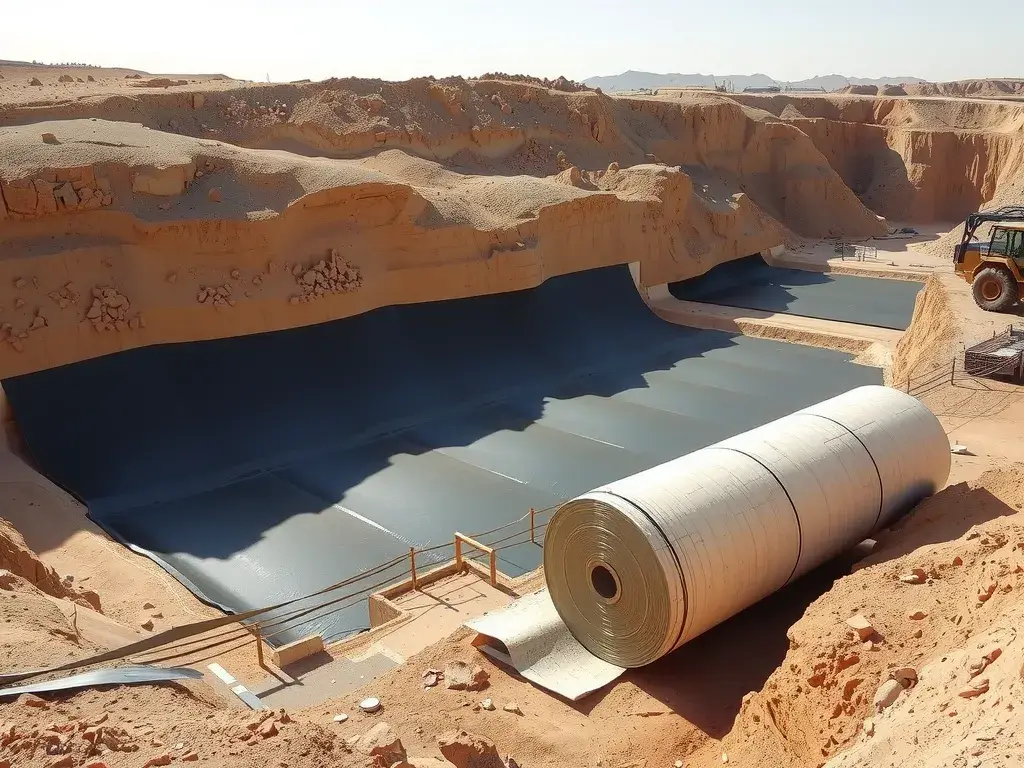

Case Study: Mining Achievements with GPF Geomembranes

A success story includes an open-pit mine in Saudi Arabia that chose GPF-manufactured geomembranes. The materials surpassed standard requirements, offering exceptional chemical resistance and mechanical durability, which enabled greater operational efficiency while ensuring environmental safety. Harsh desert conditions—high UV, thermal cycling, and abrasive winds—were addressed through resin selection, UV stabilization, and textured surfaces for slope stability. The result was smoother installation, fewer weather-related delays, and reliable containment across heap leach pads and solution ponds, all while supporting production targets. Trained crews optimized panel layout, while large roll widths reduced seams and improved logistics. The supply chain accommodated long transport distances without compromising storage or handling quality.

Harsh desert conditions—high UV, thermal cycling, and abrasive winds—were addressed through resin selection, UV stabilization, and textured surfaces for slope stability. The result was smoother installation, fewer weather-related delays, and reliable containment across heap leach pads and solution ponds, all while supporting production targets. Trained crews optimized panel layout, while large roll widths reduced seams and improved logistics. The supply chain accommodated long transport distances without compromising storage or handling quality.

The use of GPF geomembranes certified under GRI-GM13 standards was crucial in containing hazardous materials and preventing groundwater pollution, adding value beyond immediate containment to include long-term environmental care. By enabling consistent performance, the liners supported compliance reporting, stakeholder confidence, and efficient water management—key factors in arid regions where conservation is paramount. The project team paired certified materials with trained installers and documented QA/QC processes, creating a traceable record that simplified inspections during operations and will aid closure planning when the site transitions to post-mining stewardship. Integration with leak‑detection and collection systems supported continuous monitoring, and performance KPIs—seam pass rates, survey findings, repair response time—fed back into operations for continual improvement.

Conclusion

The use of technically advanced, certified geomembranes from GPF provides mining operations with more than just a protective liner; it offers a comprehensive solution aligned with strict environmental and safety protocols. Choosing products certified to GRI-GM13 and GRI-GM17 supports operational compliance and long-term ecological responsibility, positioning operations favorably in the global landscape of sustainable mining. Equally, disciplined specifications and construction—clear data sheets, traceable lot tests, skilled crews, and independent validation—convert certified attributes into reliable field performance. Thoughtful selection reduces lifecycle risk, supports production goals, and strengthens social license and ESG accountability.